Search > Range Information

Range: Technical Data

|

Technical Data |

|

| Parameters | Capability |

| Applications | Air conditioning and refrigeration |

| Connections | Copper to copper |

| Approved tube*: Copper tube conforming to |

EN 12735-1 or ASTM-B280 |

| Fitting / Tube range (inches) | 1/4", 3/8", 1/2", 5/8", 3/4", 7/8", 1", 1 1/8" |

| Fitting Material | Refrigerant grade copper (C12200 min 99.9% pure) |

| O-ring | HNBR |

| Approved oils | PVE, POE, PAO, AB and mineral oil |

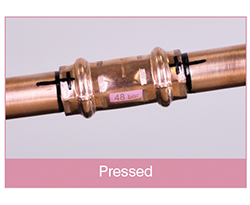

| Maximum operating pressure | 48 bar at 121°C (700 psig at 250°F) |

| Temperature range | -40°C to 140°C (-40°F to 284°F) |

|

Leak tightness |

Helium ≤ 7.5 × 10-7 Pa.m3/s at +20°C, 10 bar |

|

Vacuum |

200 microns |

| UL listing continuous operating temperature | 121°C (250°F) |

| Compatible refrigerants | R-32, R-134a, R-404A, R-407C, R-407F, R-410A, R-507, R-1234ze, R-1234yf, R-718, R-450A, R-513A, R-448A, R-449A, R-407A, R-427A, R-438A, R-417A and R-422D |

| Approvals, standards ?and code compliance |

UL 207 - file no. SA44668. UL 109 - 7 Pull Test, compliant. UL 109 - 8 Vibration Test, compliant. UL 1963 - 79 Tests of Gaskets and Seals Used in Refrigerant Systems, compliant. ISO 5149-2:2014, compliant. ISO 14903, Tightness Test, compliant. EN 378-2:2016, compliant. EN 14276-2:2007+A1:2011, compliant. EN 16084:2011, compliant. ASTM G85-11, Standard Practice for Modified Salt Spray (Fog) Testing. |

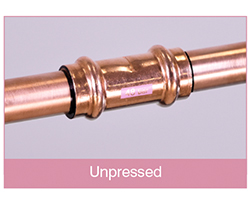

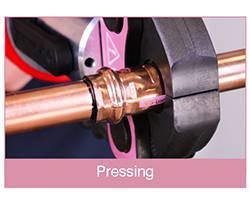

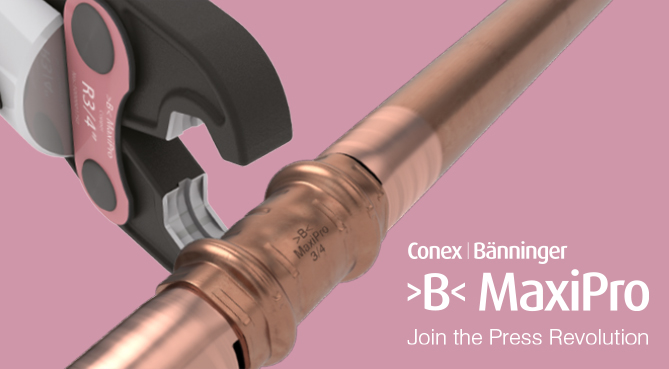

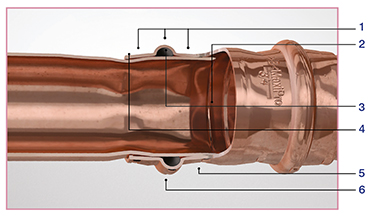

3 - Point Press:

>B< MaxiPro benefits from a 3-point press; one each side of the bead, and one press compressing the O-ring. This provides a permanent and secure joint.

1: Three press points, one each side of the bead and one press point compressing the O-ring

2: Tube stop

3: HNBR O-ring

4: Hook

5: Fitting socket

6: Bead

In tests, press fittings are up to 3 times faster to install than brazing.