Conex Bänninger Senior Technical Engineer, Colin Taylor outlines the steps to install the user-friendly Conex Bänninger >B< Press. >B< Press fittings are quick and simple to install leading to savings on labour costs, as well as offering the advantage of a flame free installation with no fire risk.

To ensure that you never miss an unpressed joint again, Conex Bänninger >B< Press developed a unique pressing indicator. A specially designed O-Ring that has a reduced section in two positions causing leaks at low pressures when not pressed (from 0.1 to 5.0 bar) and available in three colours Black-Water, Yellow-Gas and Green-Solar. Without going to full test pressure, when tested they will leak profusely alerting you to unpressed joints. The leading edge design ensures the chances of damage to the O-Rings are reduced during assembly.

When the fitting is pressed; the O-ring material compresses; filling the gaps in the O-ring to secure a leak-free path. The >B< Press profile has the advantage of a 3-point press, two mechanical presses either side of the bead, and one hydraulic press, crimping the o-ring, providing a more secure joint. When pressure is exerted through the press tool, the joint is permanently made and the fitting cannot be dismounted or re-used. Conex Bänninger >B< Press range is a cold mechanical joint which eliminates the need for solder, adhesives or additional jointing materials.

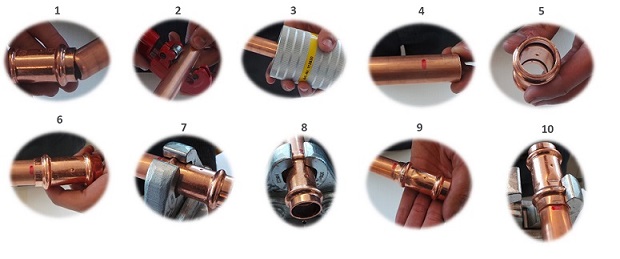

Steps to a secure fit:

Manufactured and designed in accordance with BS 8537, EN1254-8 and EN 103052, Conex Bänninger >B< Press is a versatile press fitting system for use with hard, half-hard and soft copper, carbon and stainless steel tube. They are available in Copper, Red Brass, Carbon and Stainless Steel; in sizes 12 to 108mm and are suitable for water, heating, cooling, gas and solar applications.

>B< Press fittings are compatible with various press tools and jaws.