Copper proves its mettle as preferred pipe fittings material

The advantages of copper as a pipework material have never been more important as engineers and designers strive to meet ever more exacting performance and environmental specifications. Dan Wild, UK business unit director for Conex Bänninger, discusses its many valuable properties and, in particular, how this ‘noble’ metal can help combat infections.

Uses for copper can be traced back thousands of years, to the Bronze age and beyond. It was the first metal to be cast into a shape, in around 4,000 years B.C.

Today it’s no less important, playing a key role in helping specifiers and M & E contractors enhance a building’s technological footprint while still achieving high performance and cost goals.

Corrosion and temperature resistant

As a noble metal it resists corrosion and compares favourably to steel and iron. It is highly resistant to extremes of temperature, whether those be highs or lows and in the case of a fire (its melting point is 1,085 °C) its non-flammable capabilities mean copper tube and fittings will not burn or give off toxic fumes. Copper also performs well in terms of its linear thermal expansion – or lack of it. Where the temperature rises by 30°C copper pipework will expand by just 5mm over 10 metres. While marginally bettered by steel (4mm), it matches stainless steel, is better than aluminium (7mm) and comprehensively outperforms PE (Polyethylene) (54mm) and PVC (60mm).

Anti-microbial properties

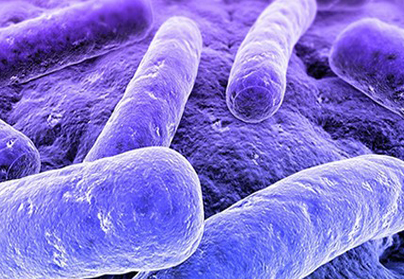

A distinctive additional benefit of copper is its anti-microbial properties, which often makes it a must when specifying plumbing solutions in healthcare and medical environments, or in community-focused situations where water hygiene is a concern.

It attacks a wide range of bacteria, including the potentially deadly legionella, and helps prevent a multitude of pseudomonas infections such as ‘swimmer’s ear’.

Direct interaction between the surface of the copper and the bacterial outer membrane causes it to rupture. As a result, the bacterium loses vital nutrients and water and dies.

This relatively newly-discovered biocidal effect of copper and copper alloys is recognised by several major scientific bodies. In 2014 the independent non-profit making ECRI Institute, whose guidance is looked to by more than 5,000 healthcare organisations worldwide, listed anti-microbial copper as ‘one of its Top 10 Technologies to Watch’.

Of course, proper water hygiene continues to be absolutely essential with EN608 taking over from BS6700 as the applicable industry standard covering ‘specifications for installations inside buildings conveying water for human consumption’. This makes copper an essential material to specify at the design stage of a new drinking water system or a refurbishment.

As a general rule for potable water, keep cold water cold and hot water hot. Up to 20°C bacteria can survive but are not active. At 60°C and above some 90% of bacteria will be killed within two minutes. The ‘optimal zone’ for bacteria to thrive is between 45°C and 60°C.

Legionella infection

Legionella pneumophila is naturally present in wholesome water and is similar to pneumonia. Its favourite habitat is biofilm, where micro-organisms have gathered to produce a slimy substance that helps more nasty ‘gunk’ stick to it. At this stage the legionella is harder to kill.

The infection is spread to humans via droplets of water that people breathe in.

Potential sources, if not properly installed and maintained, include hot water tanks, cooling towers and evaporative condensers of large air conditioning systems, such as those commonly found in hospitals, hotels and large office buildings.

Thankfully, there is a wealth of practical advice, legislation and literature available in print and online providing today’s designers, specifiers, installers and water suppliers with guidance and technical information on preventing and managing legionella and other contaminants. These range from the Health & Safety Executive’s Legionella’s Disease, the control of legionella bacteria in water systems to Water Safety in Buildings, published by the World Health Organisation.

Sustainability

From a sustainability perspective, copper has one further advantage. It is 100% recyclable. In fact, some 80% of copper ever mined is still in use today.

And while it takes 100 gigajoules of energy to refine one ton of copper, it takes only 10 gigajoules to reprocess it. So recycling is 90% better when environmental costs are taken into consideration.

Conex Bänninger has introduced a new CPD programme highlighting the advantages of copper as a preferential fitting material.

The programme is designed with specifiers and M & E contractors in mind while stockists, installers and water suppliers will also find it useful.

While focussing on copper, the programme also looks at current legislation and codes of practice, and considers the full range of products and jointing solutions on the market, from solder and braze, to compression, threaded, press and push fit. Anyone interested in attending the CPD presentation should email Richard.Smith@IBPGroup.com.